(1) The piston does not move

Verify that the oil pressure system is in operation from the flexible oil line.

Make sure all tubing is connected correctly.

Follow the in-service test procedure to correct for piston inoperability.

(2) Insufficient thrust of hydraulic cylinder

Install a pressure gauge on the oil inlet port of the hydraulic cylinder to confirm whether the pressure reaches the normal value.

If the pressure on the return side of the oil circuit is too high or the oil leakage is more than normal, it may be caused by damage to the O-ring.

(3) Temperature rise

Verify that the viscosity of the hydraulic fluid is correct.

If the fuel tank is insufficient, it must be replenished.

High room temperature will increase the temperature of the oil tank, use a cooler or fan to control the oil temperature.

(4) Pump noise

Keep out air.

If the fuel tank is insufficient, it must be replenished.

Excessive impurities accumulated in the oil tank or the quality of the hydraulic oil has deteriorated may indicate that the hydraulic pump has abnormal wear and tear and must be repaired or replaced immediately.

(5) Unknown oil leakage

Angle the drain line to expel air.

When the oil in the tank is drained, is the oil level within the scale line?

Confirm that there is no impurity blocking the vent plug of the hydraulic cylinder or the oil tank.

C Air Hydraulic Pressure Chuck Vice Claw

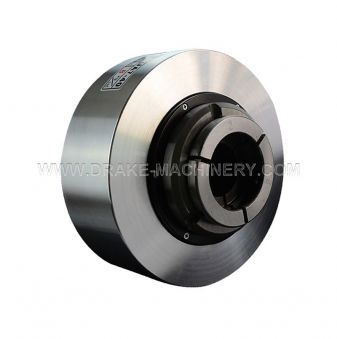

C Air Hydraulic Pressure Chuck Vice Claw  JAB High Speed Rotary Type Pneumatic Chuck

JAB High Speed Rotary Type Pneumatic Chuck  JAB-W25 Adjustable Precision High Speed Chuck

JAB-W25 Adjustable Precision High Speed Chuck  JAS Fixed Ultra Precision Diaphragm Chuck

JAS Fixed Ultra Precision Diaphragm Chuck  JAS Pneumatic Fixing Chuck

JAS Pneumatic Fixing Chuck  JA Ultra Precision Diaphragm Chuck

JA Ultra Precision Diaphragm Chuck  JA Pneumatic Rotary Quick Chuck

JA Pneumatic Rotary Quick Chuck  JB Spring Collet Back Pull Passive Chuck

JB Spring Collet Back Pull Passive Chuck