The QS2-2 Jaw Solid Pneumatic Chuck has been specifically designed to allow the use of workpiece-specific jaws for machining irregularly shaped parts, such as valves or fittings, as well as spherical parts that require full jaw envelopment. 2 jaw chuck can hold protruding parts while machining fittings or similar parts and has the long jaw travel required to machine spherical parts that must be enclosed by jaws.

This series of chuck comes with built-in cylinder structure, adopt the advanced alloy steel material, all with the surface by surface hardening treatment, in order to improve the accuracy and durability Without flange connection, D connection.

2 Jaw Chuck Feature

A 2-jaw chuck is a type of device used in manufacturing processes to securely hold and rotate a workpiece. Drake's primary goal as a manufacturer of double jaw chucks is to create a product that is durable, reliable and efficient. The following are some of the features that are typically considered when designing and manufacturing double jaw chucks.

Grip Strength: A 2-jaw chuck must have enough grip strength to securely hold the workpiece during machining or other processes. The grip strength is typically measured in pounds or newtons, and a high grip strength ensures that the workpiece remains stable and does not move during machining.

Accuracy: The accuracy of the chuck is critical to ensure precise machining of the workpiece. The chuck must be able to center the workpiece with a high degree of accuracy, ensuring that the machined surface is uniform and meets the required specifications.

Durability: The 2-jaw chuck must be able to withstand the rigors of repeated use in a manufacturing environment. The materials used in the construction of the chuck must be strong enough to resist wear and tear and maintain their shape over time.

Ease of Use: The 2-jaw chuck must be easy to install and operate, with intuitive controls and a user-friendly design. The chuck should be simple to adjust to accommodate different workpiece sizes and shapes, and should be easy to clean and maintain.

Compatibility: The 2-jaw chuck must be compatible with a wide range of machine tools and manufacturing equipment, ensuring that it can be used in a variety of different applications.

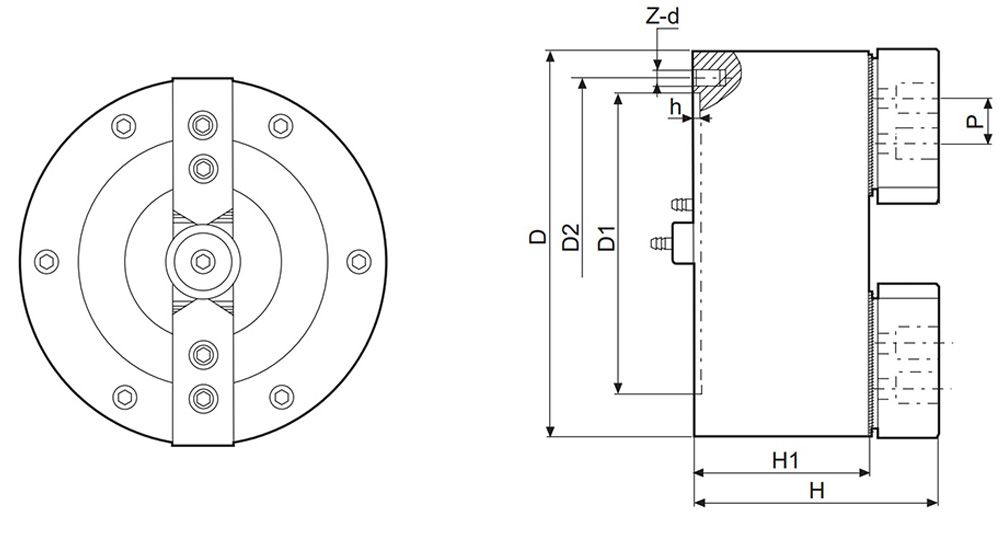

Product Drawings

Product Parameters

Discover the cnc power chuck model that suits your requirements from the following parameters. As a leading cnc power chuck manufacturer, if you have any questions regarding selection, pricing, or technical aspects, please don't hesitate to reach out. Feel free to leave your email along with your inquiries, and our dedicated team will promptly get in touch with you for professional assistance!

| Performance parameters | ||||||||

| Model/Spec. | Jaw stroke (diameter) | Maximum static clamping force KN(Kgf) | Maximum static holding force KN(Kgf) | Permissible pressure (Mpa) | Limit speed r/min | Clamping range | Holding range | Net weight (kg) |

| QS2-04" | 3.2 | 2040 | 1170 | 0.4-0.8 | 4500 | 2-120 | 15-120 | 4.8 |

| QS2-05" | 3.7 | 2856 | 1836 | 0.4-0.8 | 4000 | 3-140 | 15-140 | 7.6 |

| QS2-06" | 4.2 | 4896 | 2652 | 0.4-0.8 | 3600 | 4-180 | 20-180 | 13 |

| QS2-08" | 5 | 7140 | 4284 | 0.4-0.8 | 3300 | 5-215 | 20-240 | 21 |

| QS2-10" | 6.5 | 9282 | 6120 | 0.4-0.8 | 3000 | 10-260 | 30-280 | 33 |

| QS2-12" | 8.5 | 14076 | 9486 | 0.4-0.8 | 2500 | 10-350 | 40-360 | 66.5 |

| QS2-15" | 12 | 19788 | 15096 | 0.4-0.8 | 2000 | 20-420 | 60-400 | 112 |

| Size parameter | ||||||||

| Model/Spec. | D | D1 | D2 | H | H1 | h | p | z-d |

| QS2-04" | 115 | 72 | 100 | 96 | 72 | 3 | 16 | 3-M8 |

| QS2-05" | 135 | 95 | 108 | 118 | 85 | 4 | 18 | 3-M8 |

| QS2-06" | 172 | 130 | 142 | 130 | 93 | 4 | 20 | 3-M8 |

| QS2-08" | 208 | 165 | 180 | 136 | 98 | 5 | 25 | 3-M10 |

| QS2-10" | 252 | 206 | 226 | 143 | 100 | 5 | 30 | 3-M12 |

| QS2-12" | 322 | 270 | 290 | 160 | 115 | 6 | 30 | 6-M12 |

| QS2-15" | 400 | 340 | 368 | 168 | 118 | 6 | 43 | 6-M16 |

Related Products