HAK36 series hydraulic NC turret power to rotate with oil-hydraulic motor, quipped with conjugate cam for indexing driving tool-disc, clamping/unclamping tool-holder disk with hydraulic force, indexing and positioning with precise curvic coupling, sending signals with proximity switch. It features smart bidirectional indexing and positioning in the shortest path, high torque, high speed and silence, the accuracy of repeatability is very good and it is able to bear heavy-cutting. It has the functions of count, parity check, locking answer signal for ensuring safety in use. The turrets are widely used in various kind of NC lathe, so that the lathe can operate for facing,turning, arcing, boring, threading, grooving and parting in once hold.

1. Confirm various parameters when choosing models of turret. Choose the number of stations according to quantity of part procedure and complicacy.

2. Choose tool specifications according to model of machine tool and cutting force. Choose the front type or rear type tool turret according to the cutting directions of the machine tool.

3. After the mounting of boring cutter seat of horizontal turret, Self-bore the inner hole according to the size of boring bar and make a corresponding mark. The tool should be fixed in the former position in the later mounting.

4. The distance tool reaching out of upper housing distance is usually not more than 2/3 upper housing size. Please note when placing an order,if more than the limit.

5. Touch by hand or other things is forbidden when turret is running to avoid injury or damage.

6. If customers have any special requirements or changes in parameters, please offer some data and contact with our company.

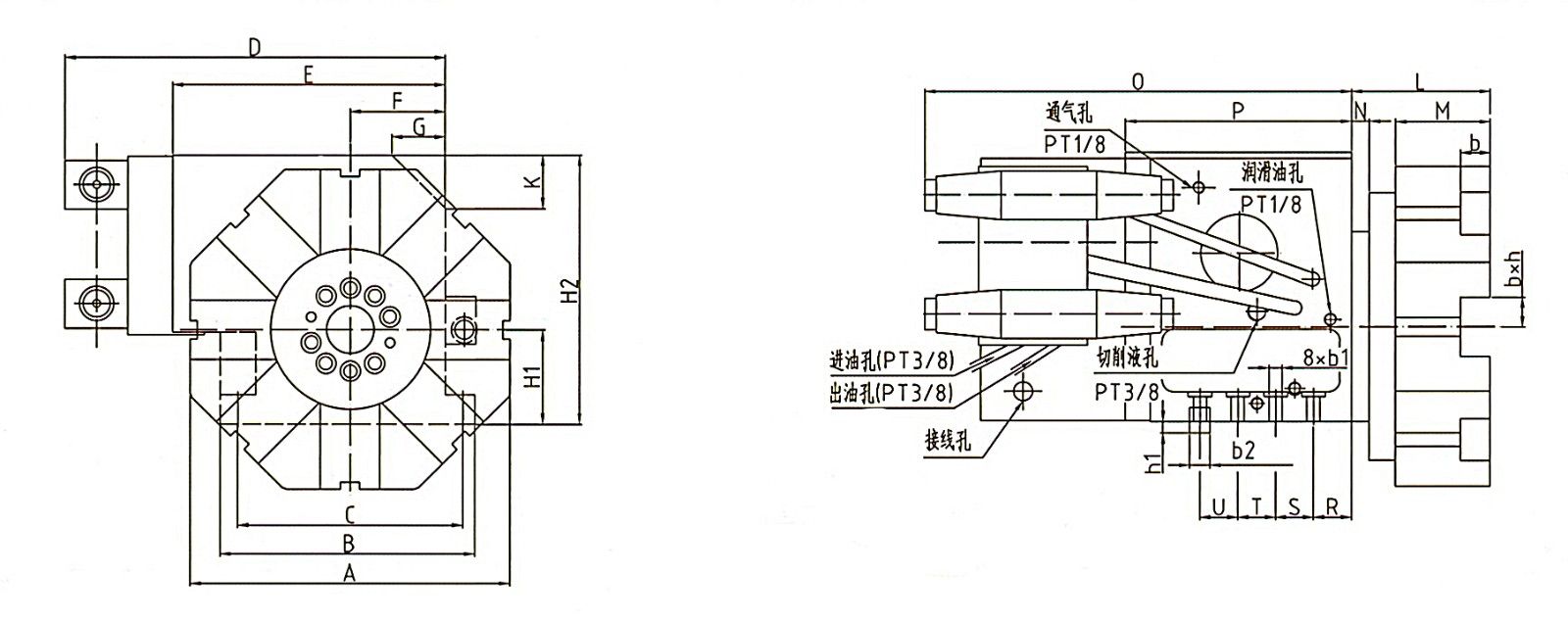

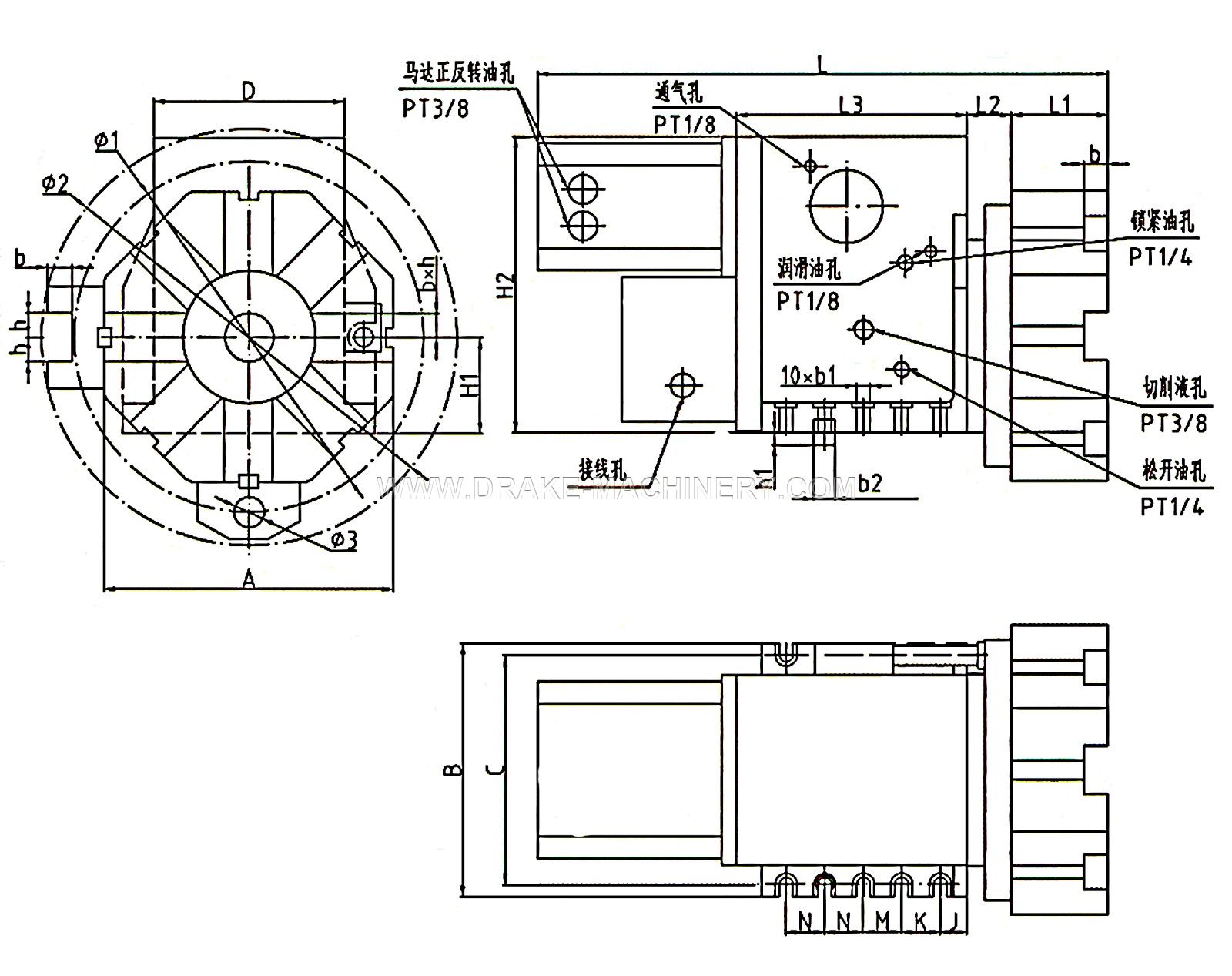

Product Drawings

Product Parameters

| Model/Data | Center height (mm) | Station number | Repeatability accuracy(") | Time of adjacent tool changing(s) | Motor power of turret(Kw) | Max.torque of cutting for power head(N·m) | Rated speed of power speed(rpm) | Hydraulic pressure(Mpa) | Flow(L/min) | |

| HAK33063 | 63 | 8 | ±1.6 | 0.25 | 0.75 | 14 | 4500 | 2.2~3 | 10 | |

| HAK33080 | 80 | 8 | 12 | ±1.6 | 0.25 | 1.5 | 19 | 4500 | 2.5~3 | 10 |

| HAK33100 | 100 | 8 | 12 | ±1.6 | 0.3 | 2 | 28 | 4500 | 2.5~3 | 15 |

| Model/Dim | A | B | C | H1 | H2 | b1 | J | K | M | N | φ1 | φ2 | L1 | L |

| HAK33063 | 190 | 168 | 143 | 63 | 230 | 11 | 25 | 30 | 30 | 30 | φ295 | φ20 | 43 | 430 |

| HAK33080 | 210 | 188 | 158 | 80 | 250 | 11 | 25 | 32 | 32 | 32 | φ340 | φ30 | 56 | 496 |

| HAK33100 | 238 | 213 | 180 | 100 | 300 | 13 | 32 | 40 | 30 | 30 | φ410 | φ40 | 65 | 540 |

Drake is a leading enterprise with 15+ years of factory experience, specializing in machine tool accessories and offering OEM & ODM services. We cooperate with over 60 countries and provide one-stop purchasing solutions for for Power Chuck, Collet Chuck, Turret, Tool Holder, Rotary Cylinder, Laser Chuck, Tool magazine, and more. Our strict adherence to international quality standards and comprehensive product range ensures tailored processing solutions for diverse customer needs.

Related Products