HAK25 series NC turret adopts 3 pieces face gear coupling as fine indexing mechanism, big screw for locking and build-in electric motor structure. It features compact structure, high precision and bearing great capability for cutting force. It can complete many procedures in once hold. It is a key attachment for NC vertical lathe and large-sized NC lathe.

1. Confirm various parameters when choosing models of turret. Choose the number of stations according to quantity of part procedure and complicacy.

2. Choose tool specifications according to model of machine tool and cutting force. Choose the front type or rear type tool turret according to the cutting directions of the machine tool.

3. After the mounting of boring cutter seat of horizontal turret, Self-bore the inner hole according to the size of boring bar and make a corresponding mark. The tool should be fixed in the former position in the later mounting.

4. The distance tool reaching out of upper housing distance is usually not more than 2/3 upper housing size. Please note when placing an order,if more than the limit.

5. Touch by hand or other things is forbidden when turret is running to avoid injury or damage.

6. If customers have any special requirements or changes in parameters, please offer some data and contact with our company.

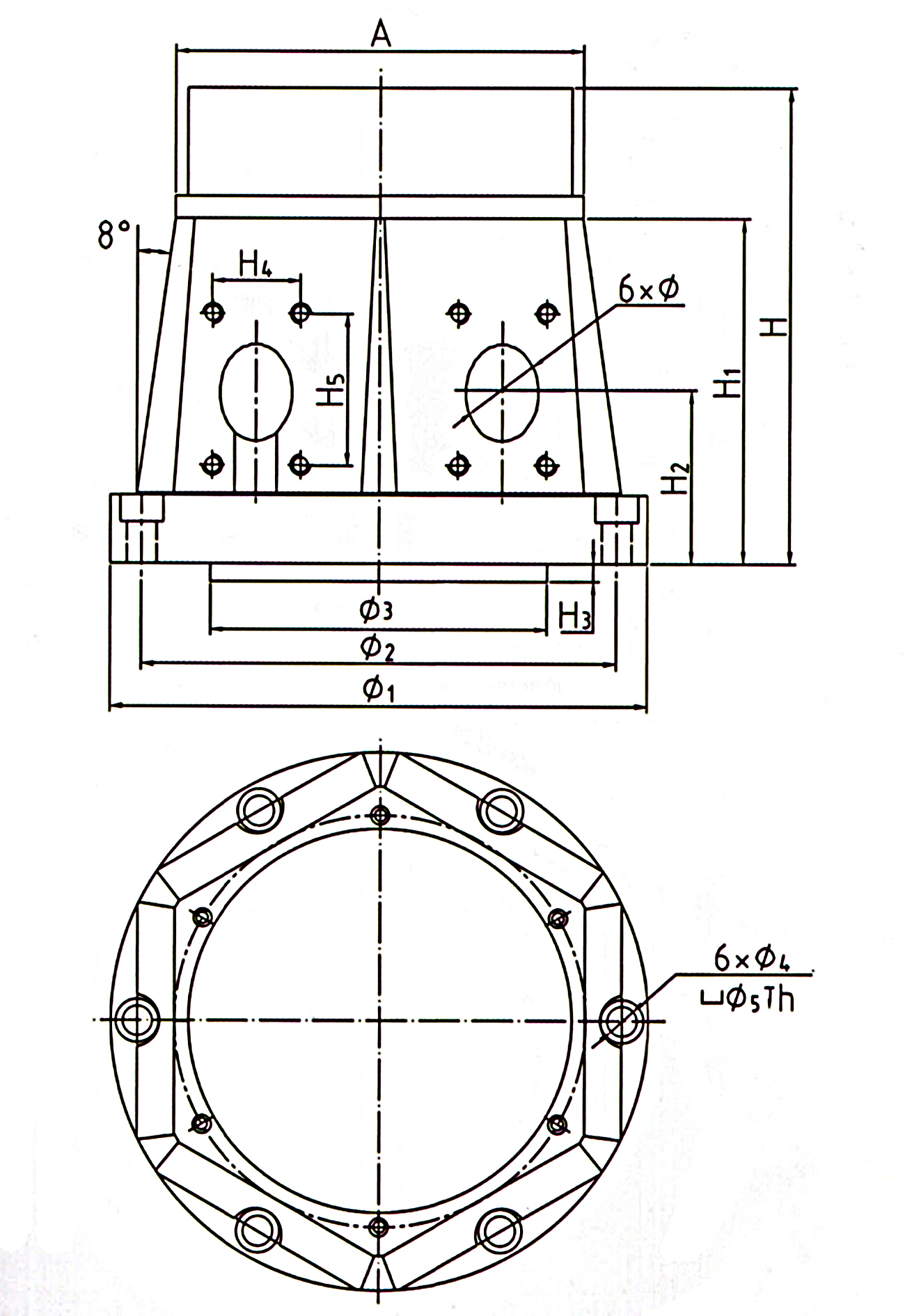

Product Drawings

Product Parameters

Please review the following parameter table. We offer various types of rotating hydraulic cylinders. If you need any assistance, feel free to leave your email and questions, and we will arrange for a professional to connect with you!

| Performance parameters | ||||||||

| Model/Spec. | Piston area (cm²) | Stroke (mm) | Hightest turnover number min-1(rpm) | Maximum working pressure MPa(kgf/cm²) | GD2 (kg.m²) | Total volume of oil drainage | Weight (kg) | |

| Press side | Pull side | |||||||

| TH428 | 53.2 | 50.5 | 10 | 8000 | 4.0(40) | 0.02 | 3 | 5.8 |

| TH536 | 69.8 | 67.5 | 15 | 8000 | 4.0(40) | 0.05 | 3 | 8.5 |

| TH646 | 97.3 | 87.9 | 15 | 7000 | 4.0(40) | 0.09 | 3 | 13.5 |

| TH852 | 146.8 | 136.6 | 20 | 6200 | 4.0(40) | 0.2 | 3.9 | 16.4 |

| TH1075 | 196.2 | 182 | 25 | 4700 | 4.0(40) | 0.4 | 4.2 | 25.8 |

| TH1291 | 250.6 | 234.1 | 30 | 3800 | 4.0(40) | 0.61 | 4.5 | 33 |

| TH1512 | 345.4 | 334.6 | 30 | 2800 | 4.0(40) | 1.5 | 7 | 50 |

| Size parameters | ||||||||||||||||||

| Model/Spec. | A I.D | B | C | D | E (h7) | F | G1 max. | G1 min. | G2 max. | G2 min. | H | J | K | L | M1 | M2 | N1 | N2 |

| TH428 | 90 | 130 | 120 | 100 | 80 | 40 | 10 | / | 35 | / | 45 | 127.5 | 155 | 6-M8×15 | M33×1.5 | 25 | M34×1.5 | 26 |

| TH536 | 105 | 150 | 135 | 115 | 100 | 50 | 15 | / | 40 | / | 47.5 | 125.5 | 170.5 | 6-M10×20 | M42×1.5 | 25 | M44×1.5 | 28 |

| TH646 | 125 | 169 | 156 | 130 | 100 | 65 | 15 | / | 40 | / | 60 | 135.5 | 193.5 | 12-M10×20 | M55×2 | 30 | M52×1.5 | 32 |

| TH852 | 150 | 198 | 188 | 170 | 130 | 70 | 20 | 0 | 45 | 25 | 66 | 145 | 198 | 12-M10×20 | M60×2 | 30 | M58×1.5 | 34 |

| TH1075 | 175 | 225 | 213 | 190 | 160 | 95 | 25 | / | 50 | / | 62 | 166.5 | 231 | 12-M10×22 | M85×2 | 35 | M84×2 | 40 |

| TH1291 | 205 | 255 | 240 | 215 | 180 | 110 | 30 | / | 55 | / | 64.5 | 180.5 | 250 | 12-M12×24 | M100×2 | 35 | M99×2 | 46 |

| TH1512 | 250 | 315 | 305 | 275 | 230 | 140 | 30 | / | 55 | / | 68 | 193 | 273 | 12-M16×32 | M130×2 | 45 | M134×2 | 46 |

| Model/Spec. | 01 H8 | 02 H8 | P | Q1 | Q2 | Q3 | R (g7) | S | T | U | V | W1 | W2 | X1 | X2 | Y1 | Y2 |

| TH428 | 30 | 28 | 101.5 | 11 | 24 | PT1/4 | 32 | 45 | 65 | 88 | 4 | 72 | 105 | / | / | 76 | M4×7 |

| TH536 | 38 | 36 | 119 | 11 | 24 | PT1/4 | 42 | 55 | 80 | 98 | 4 | 80 | 110 | / | / | 83 | M5×10 |

| TH646 | 50 | 46 | 127.5 | 12 | 30 | PT3/8 | 50 | 70 | 95 | 116 | 4 | 98 | 125 | 62 | M4×8 | 98 | M5×10 |

| TH852 | 55 | 52 | 135.5 | 12 | 32 | PT3/8 | 56 | 75 | 100 | 128 | 4 | 100 | 130 | 67 | M4×8 | 110 | M6×10 |

| TH1075 | 80 | 75 | 153.5 | 17 | 36 | PT3/8 | 81 | 100 | 125 | 158 | 5 | 115 | 160 | 92 | M4×8 | 145 | M6×10 |

| TH1291 | 95 | 91 | 165 | 21 | 34 | PT1/2 | 96 | 120 | 142 | 180 | 5 | 136 | 185 | 110 | M4×8 | 165 | M6×10 |

| TH1512 | 125 | 120 | 176.5 | 23 | 40 | PT1/2 | 130 | 160 | 204 | 218 | 6 | 160 | 210 | 171 | M6×10 | 215 | M6×10 |

Related Products