Optional chuck claw

(1)Standard Jaw;(2) Other specifications customization

(2)Jaw gripping range:first position:20-140mm; second position: 135-255mm; third position: 250-365mm.

Recommended gear

Driven gear:RY370-00-0080 driven gear (Mn4Z192)

Drive gear: RY370-00-0070 drive gear (Mn4Z32), the drive gear can be custom made.

uRecommended speed reducer and motor power

Recommended reducer: Xinbao VRB-140 reducer speed ratio: 7

Recommended motor power: 5.5KWu

Structural features:

1. One-piece fully enclosed helical gear transmission structure: higher dustproof performance and operational stability, longer service life and better user experience;

2. Convenient concentricity debugging and locking components: allow end users to easily correct the rotational concentricity of the whole machine, and enhance the accuracy and stability of the whole machine;

3. Standard claw opening in-position induction detection: The short tail cutting mode is safer, realizes automatic short tail cutting, and reduces the risk of collision of the whole machine;

4. Structural design of automatic chip removal and ash removal of the slider: automatic chip removal when the chuck is clamped, reducing the possibility of jamming and reducing the need for manual cleaning and maintenance;

5. Self-contained channel steel I-beam jaws: up to 28 gauge I-beam and 28 gauge channel steel.

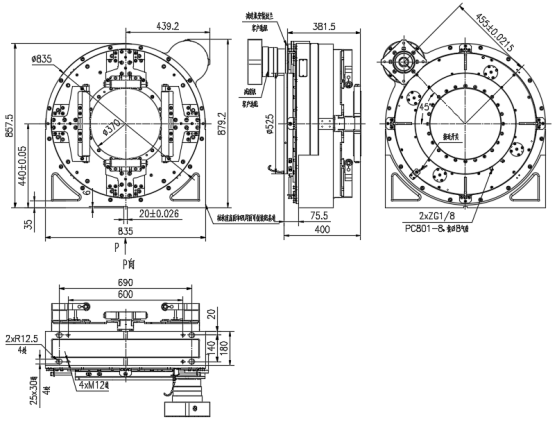

Product Drawings

Product Parameters

| Specification | Outer Diameter( mm) | Centre-height (mm) | Total Weight (Kg) | Inertia (K g.cm ²) | Repeatability (mm) | Rotary precision (mm) |

| Φ 415 | 215±0.05 | 380 | 48000 | ≤0.15 | ≤0.15 | |

| RY350-10-0000 | Single jaw stroke( mm) | Single Claw thrust(KN) | Processing Range(mm) | Permissible pressure (M pa) | Rated speed (rpm) | IP Grade |

| 42 | 4.5±10% | 20-355 | 0.3-0.9 | 150 | / |

| Appropriative jaws can be customized according to pipe fittings | |

| Selection criteria | GB / T3094-2000 Cold drawn special-shaped steel pipe GB / T706-2008 Hot-rolled Steel GB / T17395-2008 Seamless Steel Pipe Size, shape, weight and allowable deviation |

| Chuck model | RY350 rear chuck |

| Clamp range | The first jaw: The first position of inner clamp:20-95mm, second position: 70-145mm; The second jaw: The first position of inner clamp:140-215mm, second position:190-265mm; The first position of outer support : 230-300mm, second position: 280-355mm; I-beam and channel steel jaws: first position:165-240mm,second position:215-295mm. (specification within the allowable load-bearing range) |

Jaw length | The first jaw length: short jaw 135mm, long jaw 300mm; The second clamp jaw length: inner clamp 160mm, outer support 25mm; I-steel channel jaw 48mm. |

| Round tube | Clamping 20-265mm (the second clamping position:140-265mm), the external support:230-355mm; individual specifications needs to customize appropriative jaws.) |

| Square tube | The maximum size of the square tube is 140 x140 mm by the first jaw, the maximum size of the square tube is 250 x 250mm by the second jaw; the other specifications need customized special jaws; |

| Rectangular tube | The minimum length of the short side is 20mm, and the maximum length of the long side is 250mm for rectangular tube(The maximum value is 250x200mm); other specifications need to customize appropriative jaws; |

| Oval Tube/Flat Oval Tube | The minimum length of the short axis is 20mm, and the maximum length of the long axis is 250mm for oval tube; other specifications need to customize appropriative jaws; |

| I-beam | Using I-beam channel steel jaws can hold up to No. 28 gauge I-beam; |

| Channel steel | sing I-beam channel steel jaws can hold up to No. 28 channel steel |

| Equilateral angle steel | The first jaw can hold up to No. 12.5; The second jaw can hold up to No. 14; other specifications need to customize appropriative jaws; |

| Unequal angle steel | The first jaw can hold up to No. 12.5/8; The second jaw can hold up to: No.20/12.5.; other specifications need to customize appropriative jaws; |

Related Products